08.09.2023

+++ Processes and systems become faster, more efficient and more transparent +++ BMW Group MINI Plant Oxford as forerunner +++

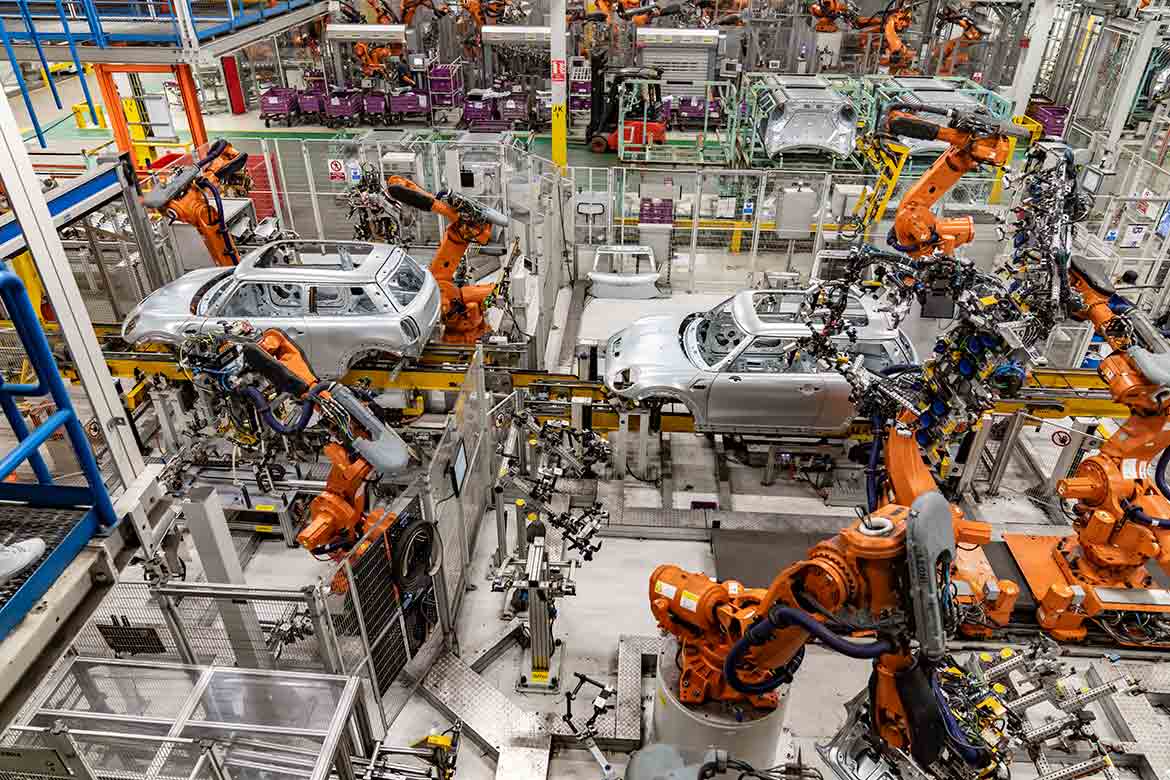

Munich / Oxford. Another step in the digitalization of BMW Group production has been taken: in August, the new standardized BMW IT solution for production plants went live for the first time worldwide at the MINI Plant Oxford. Based on modern, private cloud-based software and SAP S/4 HANA, the BMW Group and SAP SE are further developing the process and tool landscape for the entire automotive industry, thereby establishing state-of-the-art technology in the industry.

First successful SAP S/4 HANA go-live in automotive production. With the implementation at the Oxford plant, the two companies have created a blueprint for process digalitization of (automotive) plants of the future. The simultaneous rollout of the new global logistics, finance and customs process solutions is the basis for future global standardization with SAP S/4 HANA, SAP Analytics Cloud and SAP GTS. The standardization enables mutual plant support, flexible employee deployment and synergy effects in support and training. It also forms the basis for future innovations and a faster rollout of new solutions in the production network and enables data consistency and transparency along the entire value chain. By linking relevant product, process, quality, financial and cost data using data analytics and AI, the BMW Group is taking plant management to a new level.

“The go-live at the Oxford plant is an important milestone in the digitalization process of our production. It is further evidence of the transformation that is anchored in the BMW iFACTORY. It is the starting point of one of the largest change projects in the history of our production network. The new IT standards will be implemented successively at our BMW Group production sites,” says Michael Nikolaides, Head of Production Network, Logistics at the BMW Group.

With the BMW iFACTORY, the BMW Group is defining the future orientation of its plants and manufacturing technologies. Alongside the aspects of LEAN and GREEN, the digitization of production is the central element of the transformation. Digitalization and innovative technologies already have an impact along the entire BMW Group production value chain and are being driven forward in the following technology clusters: Smart Data Analytics, Smart Logistics, Innovative Automation & Assistance Systems and Additive Manufacturing. Especially in the area of BMW Group Logistics, Customs and Controlling, the introduction of the new production IT standards will further increase the level of speed, quality and flexibility.

“IT is business and business is IT. As one team, we have successfully implemented a highly complex project. As part of our digitization and harmonization strategy, with this new solution we are now able to link relevant product, process, quality and cost data, enabling data consistency and transparency across the entire production chain. We are proud to be the innovation leader in the standardization of business processes and systems in the automotive industry,” says Alexander Buresch, CIO and SVP Group IT at BMW Group.

With this go-live, Oxford is the hub of the process digitalization and harmonization strategy. The MINI Plant in Oxford is the first of the BMW Group’s networked factories to be converted to the cloud architecture over the next few years. Future innovations can thus be rolled out much faster across all plants.

Co-innovation of two German pioneers: BMW Group and SAP SE define new standards for automotive industry. More than 1,000 colleagues from both companies were involved in the project. In it, SAP SE and BMW AG further developed the functionalities of S/4HANA for use in the automotive industry. Both companies can look back on a strategic partnership spanning more than 30 years, during which numerous co-innovation projects have already been successfully implemented.